|

Resources

Videos

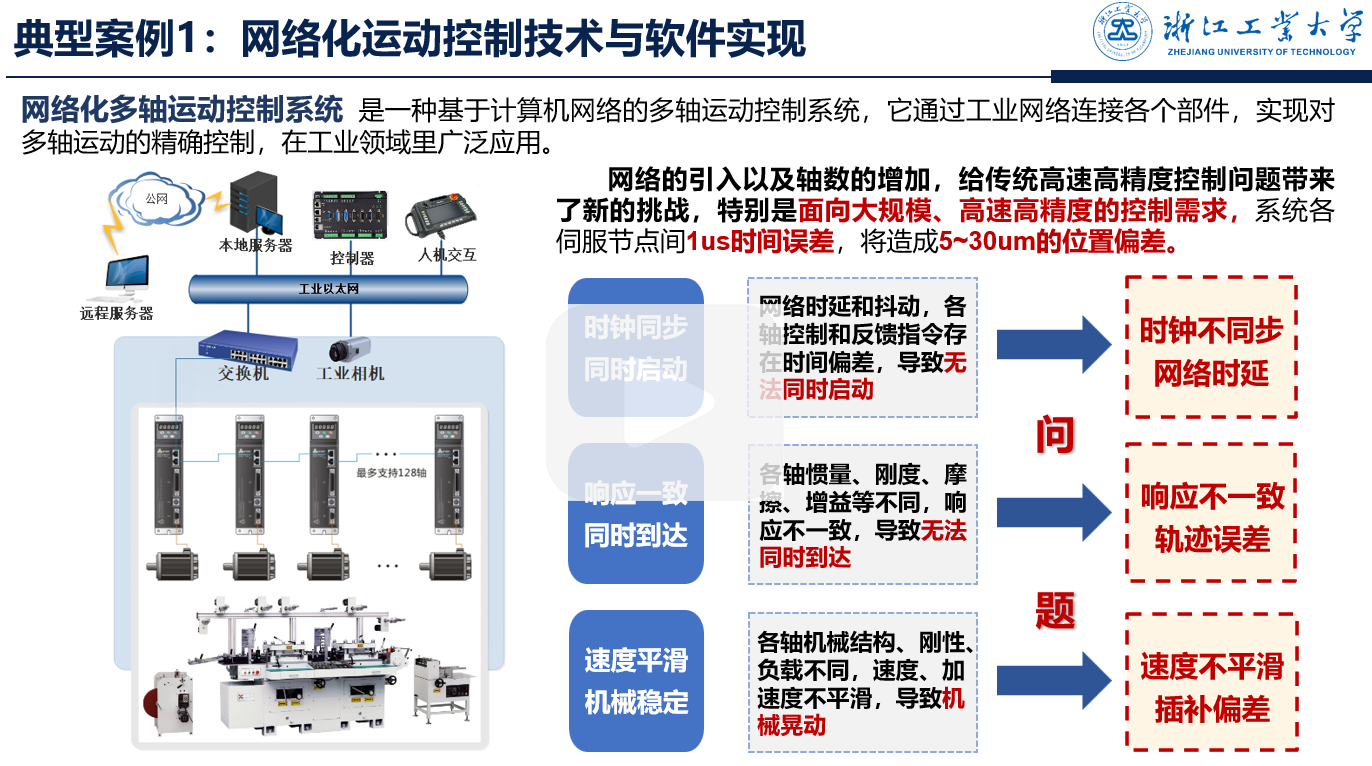

Networked Motion Control

Owing to the swift advancement of Ethernet technology and the escalating need for

intelligent transformation in manufacturing, motion control systems that operate on

universal Ethernet have emerged as a prominent area of research. These networked systems

offer several benefits including streamlined wiring, reduced system coupling,

enhanced scalability, and simplified maintenance. Consequently, they have found extensive

applications in various sectors such as laser engraving, printing, welding tongs, and textiles.

However, the introduction of the Ethernet technology into the motion control system brings

new problems, such as network-induced delay and packet loss.

To achieve high-precision motion control, methods such as active disturbance rejection control,

equivalent input disturbance, and intermediate observer are used to estimate and compensate for disturbances in real-time.

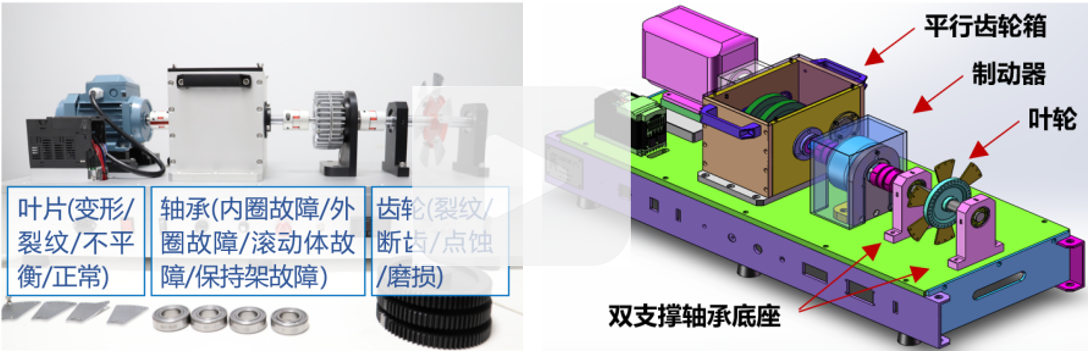

Fault Prognostic and Health Management for Rotating Machinery Equipments

data acquisition cards, signal conditioning modules, and a computer for

experimental data analysis. By substituting the components of the device

with damaged parts, we can simulate single-point or composite failures.

An effective and interpretable approach for managing the health of

rotating machinery involves integrating physical model constraints into

data-driven methods, such as physics-informed deep learning and feature extraction.

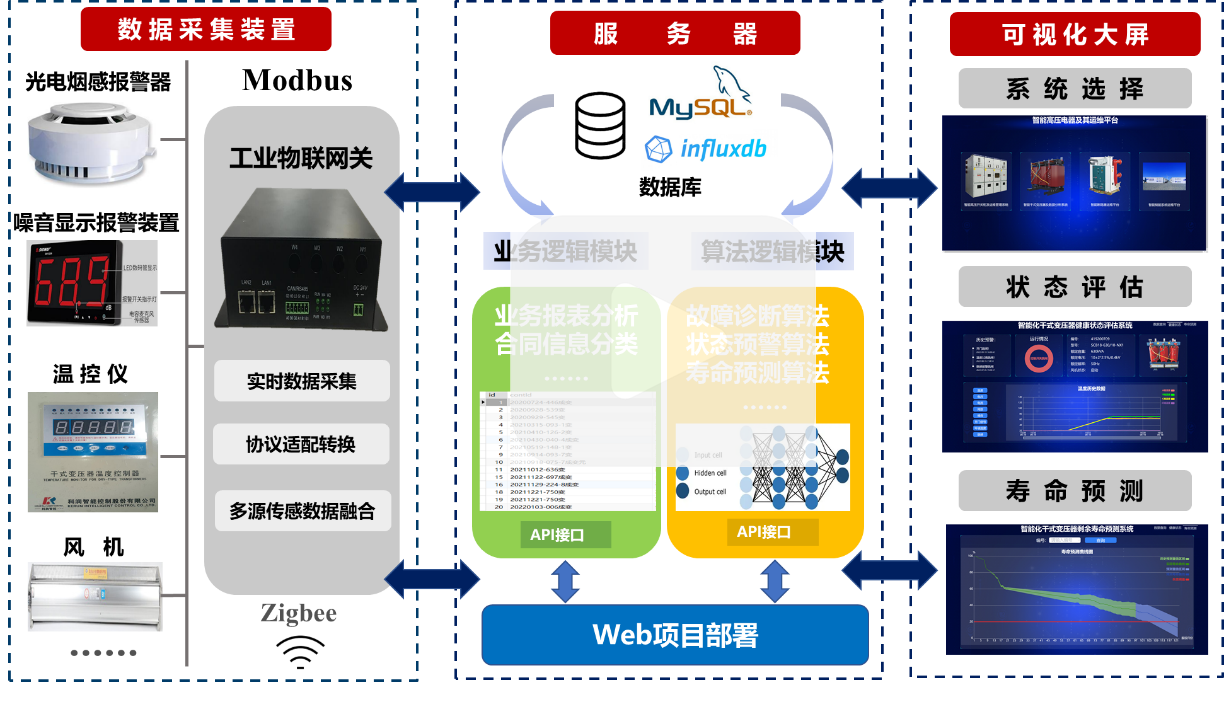

Intelligent dry type transformer and data analysis system

|

|

Dry-type transformers, vital components within power systems,

serve as the key link for transmission and transformation networks.

The intelligent data analysis system designed for dry-type transformers proves instrumental in ensuring their efficient operation and maintenance.

This innovative system amalgamates Internet of Things (IoT) technology, network communication protocols, big data analysis,

and artificial intelligence, tailoring it for end-user applications. Our project addresses prevalent challenges,

including the limited intelligence of dry-type transformers and the complexities associated with remote servicing in operation and maintenance management.

Through the integration and extraction of multidimensional sensing data within the transformer,

the system achieves proactive early warning capabilities. These include self-perception of internal equipment status,

intelligent status diagnosis, automatic trend tracking, and early detection of abnormalities. Additionally,

we establish a remote operation and maintenance management platform for transformers, enabling functions such as acquiring operational data, real-time monitoring,

fault diagnosis, life prediction, and comprehensive operation and maintenance management.

Discrete Manufacturing Industry Oriented Industrial Software

Codes:开源代码

- FL-LDP

This is a code that combines federated learning with differential privacy for transformer fault diagnosis.

|